Pistol grip grease gun with flexible hose

Pistol Grip Grease Gun with Flexible Hose is a revolutionary tool designed for efficient and hassle-free lubrication. This high-quality grease gun off...

Pistol Grip Grease Gun with Flexible Hose is a revolutionary tool designed for efficient and hassle-free lubrication. This high-quality grease gun off...

Crafted with top-notch durability, this grease gun boasts a sturdy aluminum construction that can withstand even the toughest conditions. Its heavy-du...

Hangzhou Taihong Hardware Tools Co., Ltd. was established in 2004�� located in Xiaoshan, Hangzhou Zhejiang, China, and is China Stol Grip Grease Gun Manufacturers and Heavy Duty Pistol Grip Grease Gun Suppliers, and some related accessories of automotive tools.

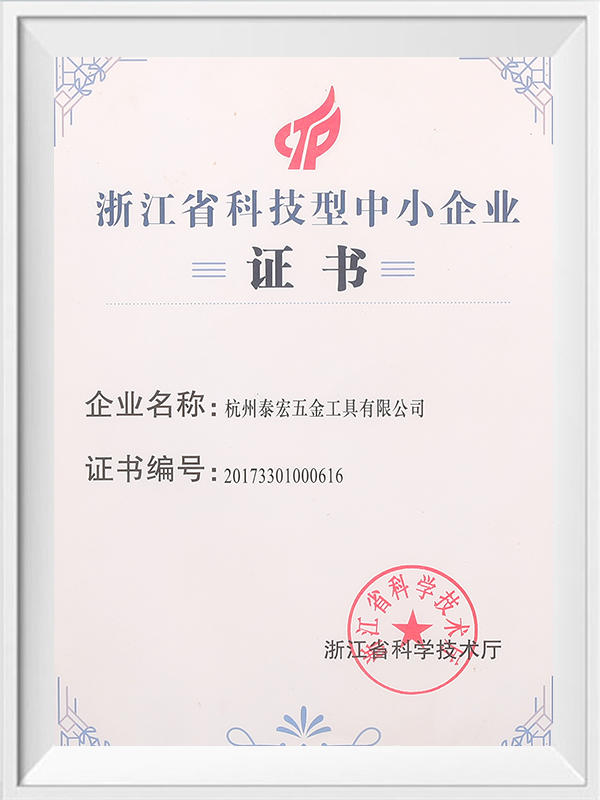

From our foundation time, we have regarded "Your satisfaction, our pursuit' as our highest work target. Our company pays much attention to the corporate culture, valuing the employee's ability and drawing on all the comers of the company. At the same time, we have obtained the provincial-level certificate of technical innovation in 2017 through our research and development.

Our products are mainly exported to Europe, North America, South America, Southeast Asia, Japan, and Korea, With high quality and professional after-sales service, our products have won high reputations among our customers both at home and abroad. We sincerely look forward to establishing long-term business relationships with clients all over the world on the basis of principles of equality and mutual benefit.

Our 20 years of production experience has created Taihong's corporate value.

The company has always adhered to the principle of "sincerity-oriented, quality-based, talent-based factory", strictly implements the ISO9001:2008 quality system standard, and actively develops and improves products. In 2017, it was rated as a small and medium-sized technological enterprise in Zhejiang Province.

ISO9001

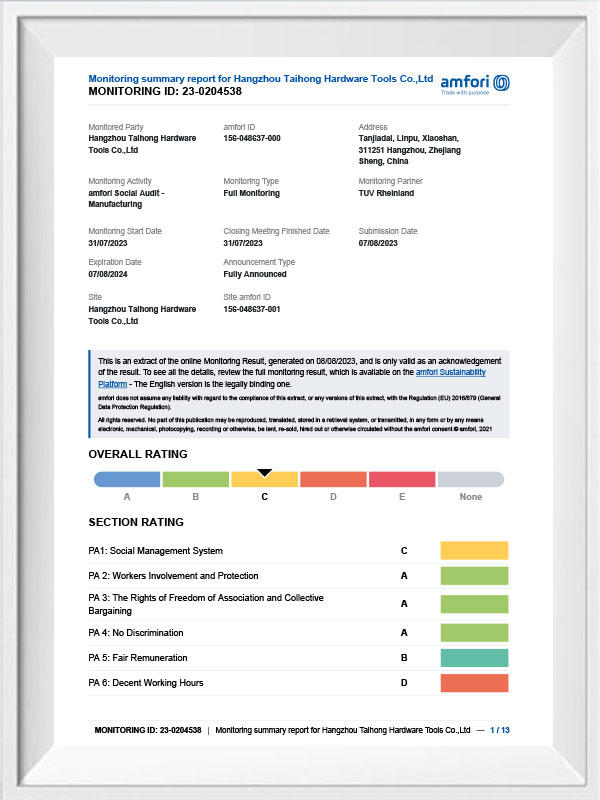

MONITORING-ID-23-0204538

High-tech Enterprise Certificates

High-tech Enterprise Certificates

Zhejiang Province Science and Technology-based Small and Medium-sized Enterprises Certificate

Consumer Confidence Unit

In the realm of industrial lubrication, miniature grease guns are making significant strides, offering a host of advantages o...

READ MOREPistol grip aluminum grease guns play a pivotal role in various industries, primarily in lubrication, maintenance, and energy...

READ MOREJapanese-type grease guns, also known as lever-type grease guns, stand out in the realm of lubrication equipment for their e...

READ MOREIn industrial, automotive, marine, and agricultural settings, fluid extraction is a routine task essential for maintenance an...

READ MOREGrease gun kits are indispensable tools in industrial maintenance and lubrication, comprising several key components designed...

READ MOREJapanese-style grease guns offer unique features and advantages compared to traditional grease guns, making them preferred ch...

READ MORE